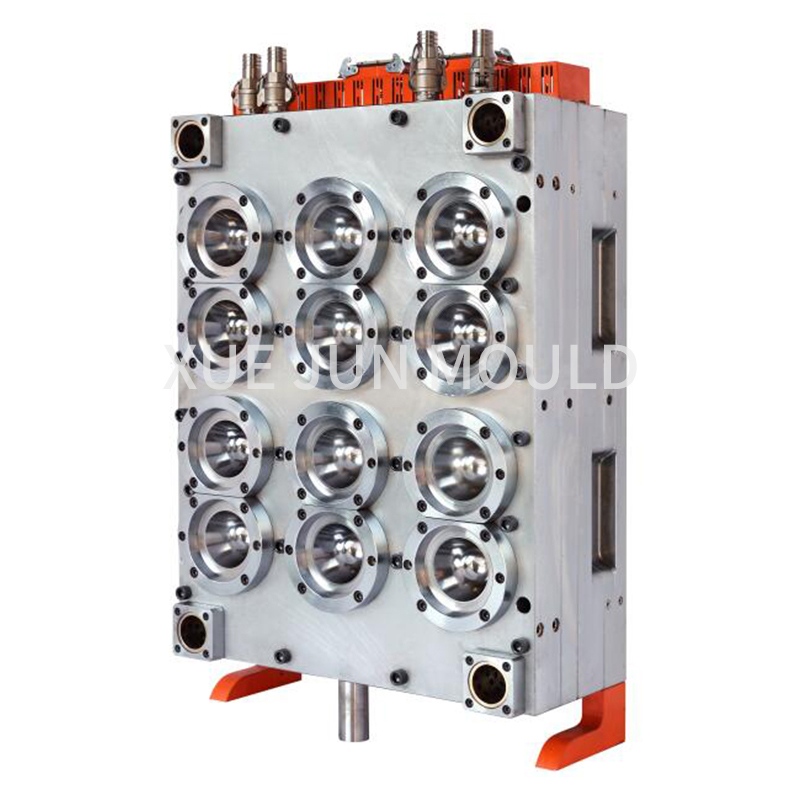

Designing a 12cavity PET jar preform mold is a complex engineering task that requires consideration of multiple factors, including the shape, size, wall thickness, material properties, and production efficiency of the preform. The following are the design features to consider when designing 12cavity PET jar preform mold:

Mold structure design: 12cavity PET jar preform mold needs to have a corresponding mold structure to accommodate 12 bottle preforms while ensuring the stability and durability of the mold structure. Common structures include split molds, sliding molds, etc. It is necessary to choose the appropriate structural design according to production needs.

Preform shape and size: The shape and size of PET preforms are crucial to mold design. Designers need to determine the shape, capacity, diameter, height and other parameters of the preform based on actual needs, and design the inner cavity structure and molding contour of the mold accordingly.

Preform wall thickness control: The wall thickness of PET bottle preforms directly affects the quality and molding cycle of the preforms. Mold design needs to consider how to achieve uniform distribution and precise control of preform wall thickness to ensure consistent quality for each preform.

Material selection: Mold materials need to have high strength, high hardness, wear resistance and corrosion resistance to adapt to long-term and high-intensity production operations. Commonly used materials include high-quality alloy steel or stainless steel.

Cooling system design: The cooling system is crucial for PET bottle preform molds, which directly affects the molding cycle and production efficiency. Designers need to rationally layout the cooling channels to ensure that the cooling water can fully cover the surface of the preform and effectively take away heat to increase the molding speed.

Exhaust system design: The exhaust system can effectively avoid the generation of bubbles inside the mold and improve the surface quality and transparency of the preform. Designers need to reasonably set the location and number of exhaust ports to ensure that the gas inside the mold can be discharged smoothly.

Surface treatment: The mold surface requires precision machining and surface treatment to ensure smoothness and accuracy of the preform surface. Common surface treatment methods include polishing, electroplating, etc., which can improve the service life and molding quality of the mold.

Automation design: In order to improve production efficiency and automation, designers need to consider how to realize automated mold operations, including the design and implementation of automatic mold opening, automatic demoulding, automatic cleaning and other functions.

In general, designing a 12cavity PET jar preform mold requires comprehensive consideration of preform shape and size, wall thickness control, material selection, cooling system design, exhaust system design, surface treatment, automation design and other aspects to ensure that the mold can Meet production needs, and have stable production performance and high-quality preform forming effects.